In any workshop, safety should always be the top priority, especially when working with heavy-duty equipment and machinery. Clamping solutions are crucial for securing workpieces during tasks like cutting, welding, and grinding. Fixto clamping solutions provide high-quality, durable options for these processes, but safety measures must be taken to ensure optimal performance. In this blog, we will discuss essential safety tips for using Fixto clamping solutions in the workshop. By following these guidelines, you can ensure a safer work environment and increase the overall efficiency of your projects.

Understanding the Importance of Clamping Safety

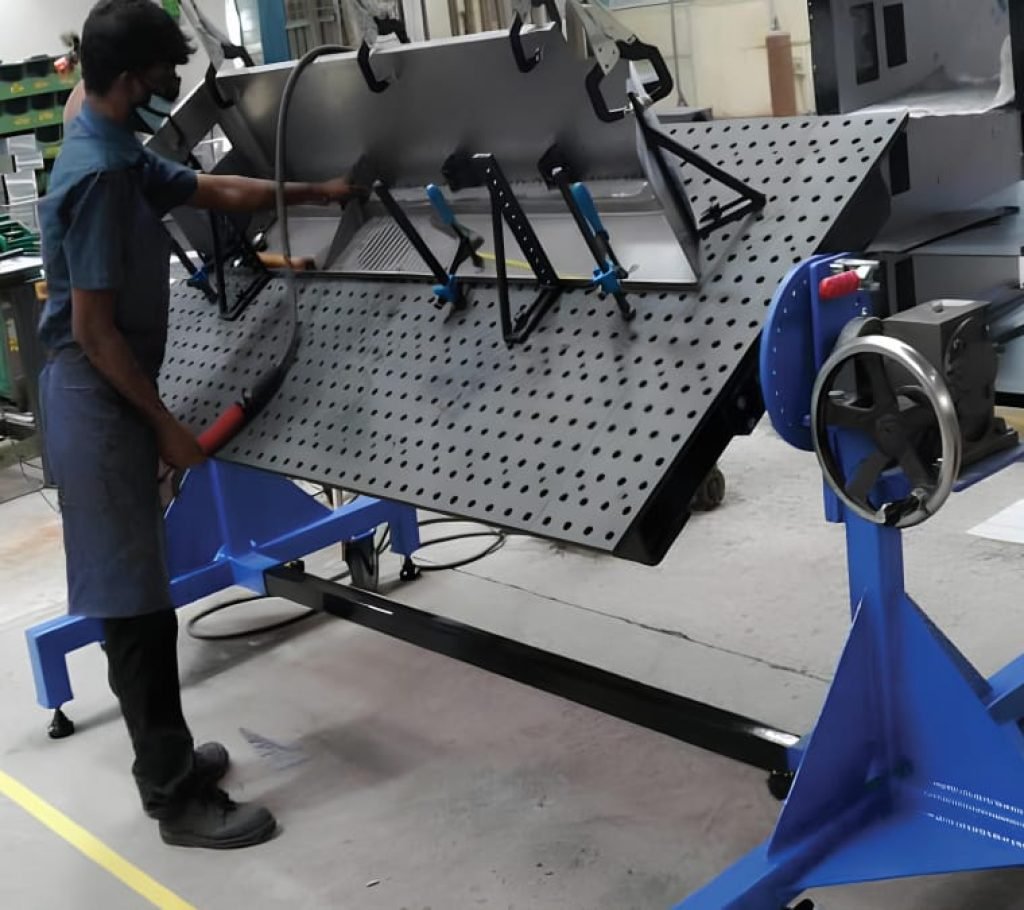

Clamping plays a significant role in ensuring the stability and security of workpieces during fabrication. Without a solid clamp, a workpiece can shift, causing inaccuracies, damaged materials, or even accidents. Fixto clamping solutions are designed with precision and durability in mind. However, like all equipment, they require careful handling to maintain safety and functionality. By understanding the importance of using the right clamping techniques, you can prevent costly mistakes and ensure the safety of everyone in the workspace.

“Always check Fixto clamping solutions for wear, cracks, or rust before use. This ensures optimal performance and prevents potential failure during operation, promoting workshop clamping safety.”

Safety Tips for Using Fixto Clamping Solutions

Choose the Right Clamping Solution for Your Task: Select the appropriate Fixto clamp based on the workpiece’s size and material. Ensure the clamp’s capacity matches the task’s demands to avoid instability or damage.

Inspect Clamps Before Use: Check for signs of wear, cracks, or rust on your Fixto clamping solutions. Always ensure the clamp is in good condition to guarantee optimal performance and prevent failure during use.

Secure the Workpiece Properly: Firmly position the workpiece and apply even clamping pressure using your Fixto clamping solutions. Ensure the piece is stable, with no movement that could lead to inaccuracies or accidents.

Use Clamps Within Their Rated Capacity: Never exceed the rated load capacity of your clamp. Overloading can lead to clamp failure and potential injury or damage to the workpiece.

Maintain Proper Clamping Technique: Tighten the clamp evenly and with consistent pressure. Avoid jerky movements, and use the appropriate tools to achieve the correct clamping force.

Avoid Placing Hands Near the Clamping Area: Keep your hands away from the clamping zone to prevent injury when using Fixto clamping solutions. Always use tools or scrap material to adjust clamps without risking accidental pinching, ensuring workshop clamping safety.

Keep the Work Area Clean and Organized: A clutter-free workspace enhances workshop clamping safety by reducing the risk of accidents. Ensure the work surface is level and the area around the Fixto clamps is clear of debris for optimal performance.

Follow Manufacturer Instructions: Adhere to Fixto’s specific guidelines for safe use and maintenance. This ensures maximum performance and extends the lifespan of your clamps.

Regularly Maintain Fixto Clamping Solutions: Perform routine inspections and maintenance on your clamps. Keep components lubricated and replace damaged parts to maintain safe and efficient operation.

Conclusion

Using Fixto clamping solutions in the workshop can significantly improve the efficiency and precision of your tasks. However, safety should always be the priority. By selecting the right clamping solution, inspecting and maintaining your equipment, securing workpieces correctly, and following proper clamping techniques, you can prevent accidents and improve the overall safety of your workspace.

Whether you’re working on small tasks or large, complex projects, Fixto’s clamping solutions offer the reliability and precision needed for optimal results. Remember, safety is key to ensuring that your clamping solutions work effectively and that your workshop remains a secure environment for everyone.