What’s the Article About? A high-precision automotive fabrication depends on the right welding table accessories. Below are listed and explained 5 such tools: Fixto’s solutions enhance accuracy, reduce setup time, and ensure consistent, professional-grade weld quality.

For any type of weld to be able to be carried out effortlessly and efficiently, apart from the table, its accessories play an important role. Be it welding table clamps, rotary weld positioners, or any kind of holder, from base-level work to exhaustive and complex structures, such accessories also help to define the quality of the final build. Hence, if a solid welding table is the foundation, it’s the welding table accessories that unlock its true potential, giving high-precision results. Therefore, the right tools, like those of Fixto, are a prerequisite to yield good results, reduce setup time, improve alignment, and ensure consistent weld quality.

Ball Lock Bolts

It is one of the most underrated accessories in precision welding setups. Such bolts allow fast and secure locking, facilitating the fabricators to quickly fix clamps, stops, and various types of fixtures onto the welding table without compromising alignments and welds. In today’s modern space, welds are automotive, which further need setup changes frequently, and wherever time efficiency matters the most, ball lock bolts are the primary ones to recess such adjustment timings.

But what makes the lock bolts so convenient to use? Ball lock bolts are one welding table accessory, which is equipped with a spring-loaded locking mechanism. This ensures a tight and vibration-resistant hold, which is further essential when the weld is exposed to high heat and movement. Not just this, but ball lock bolts enable repeated positioning, which is useful for batch production of brackets and mirrored automotive parts. For shops that focus on speed without compromising on accuracy, such ball lock bolts are a basic tool.

Welding Table Clamps 16 mm

As its name itself suggests, this welding table clamps 16mm is designed to fit the said 16 mm hole systems. They not only provide modular flexibility but also consistently and seamlessly align across complex setups. Such clamps being the standard, they allow fabricators to integrate orderly with other accessories such as locating blocks, stops, and positioning pins. In big and automotive applications, welding table clamps excel in holding uneven and/or heavy components firmly in place.

Clamps need to be strong enough to handle an uncontrollable situation; therefore, Fixto’s clamps, which are 16 mm, ease fabricators’ operations by preventing any kind of heavy movement caused by any kind of factor. They also improve repeatability and workflow efficiency. Such clamps are also crucial for professional-grade standards.

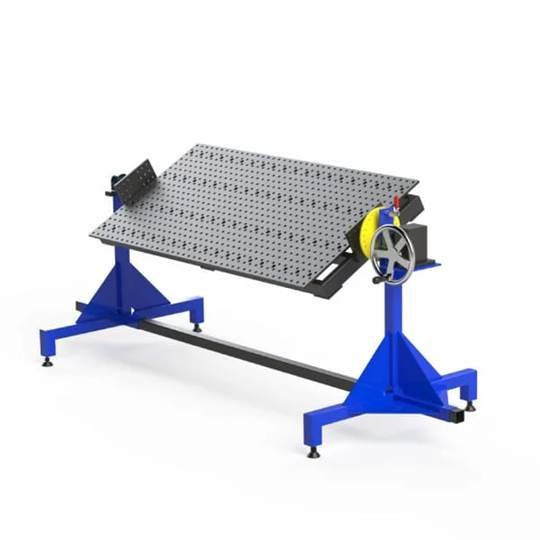

Rotary Weld Positioner

You might’ve gotten the essence after reading the name. The rotational movement of the rotary weld positioner is a game-changer in the fabrication industry. It is used in welding circular or tubular automotive components. Though it moves in a circular direction, it is a controlled movement, allowing welders to maintain optimal welding positions throughout the process. This further helps in consistent bead appearance, better insertion, and reduced weld reworks.

At times, while changing the positions while welding an object using conventional machines, such rotary weld positioners reduce welder’s fatigue by eliminating awkward body positions and repeated manual repositioning. Not only this, but such a positioner enhances productivity and safety, which is also good for the final result. For the shops and industry players who are aiming to achieve both precision and efficiency, this accessory is a strategic investment.

Squaring & Locating Blocks

One thing that Fixto’s squaring blocks do is maintain exact angles and alignments during the fabrication process. Many automotive components require 90-degree or multi-axis positioning; therefore, the square and locating blocks help in the scope. Moreover, when paired with welding table clamps, they ensure components remain seamlessly aligned throughout the process.

These blocks are so rigidly constructed that they resist heat bending and maintain accuracy even during long welding cycles. For a better understanding of its usage, squaring blocks are particularly useful for frames, brackets, and mounting points where mathematics affects performance differently: the symmetry and the geometry.

Adjustable Stops & Positioning Pins

Flat Stops that are adjustable help in repeatability. Such accessories define fixed reference points on the welding table, further allowing fabricators to place parts in the same or desired position every time. This phenomenon also facilitates the fabricators to be at ease when multiple identical components or mirrored parts are used at the same time.

Both of them—the positioning pins and adjustable stops—go hand-in-hand. Pins lock into the table holes to establish alignment, while the stops control part placement along the specific dimensions. Coming together they minimize setup variation and reduce production time by a larger difference. Now, when measurement errors and manual alignment are eliminated, consistency improves, making it a durable end result.

Final Statement: Fixto’s Welding Tools Are Worth Your Investment

It’s not just about the skills when we talk about high-precision automotive fabrication. You also need the right tools for the same. Fixto’s ball locks, adjustable stops, and welding table clamps are the accessories that play a critical role in facilitating accuracy, efficiency, and weld quality. Investing in the right welding table accessories will not only improve results but also help workshops of each segment to deliver reliable, professional, and overall handy automotive products and services.

FAQs

1. Why are welding table accessories important for automotive fabrication?

It’s because they improve accuracy, stability, and replicability, which are essential for proper fixtures and safety.

2. Are 16 mm welding table clamps better than standard clamps?

Yes, they offer systematic similarity and higher precision for modular setups.

3. When should a rotary weld positioner be used?

It’s mainly for tubular or circular components where consistent weld angles are required.

4. Do squaring blocks really improve accuracy?

Yes, not only do they ensure precise angles but also help in alignment throughout welding.

5. Are adjustable stops useful for small workshops?

Definitely, the stops save time and reduce errors in both small- and large-scale fabrication.